What Is a Carbide End Mill Used For?

Precision Cutting with Carbide End Mills

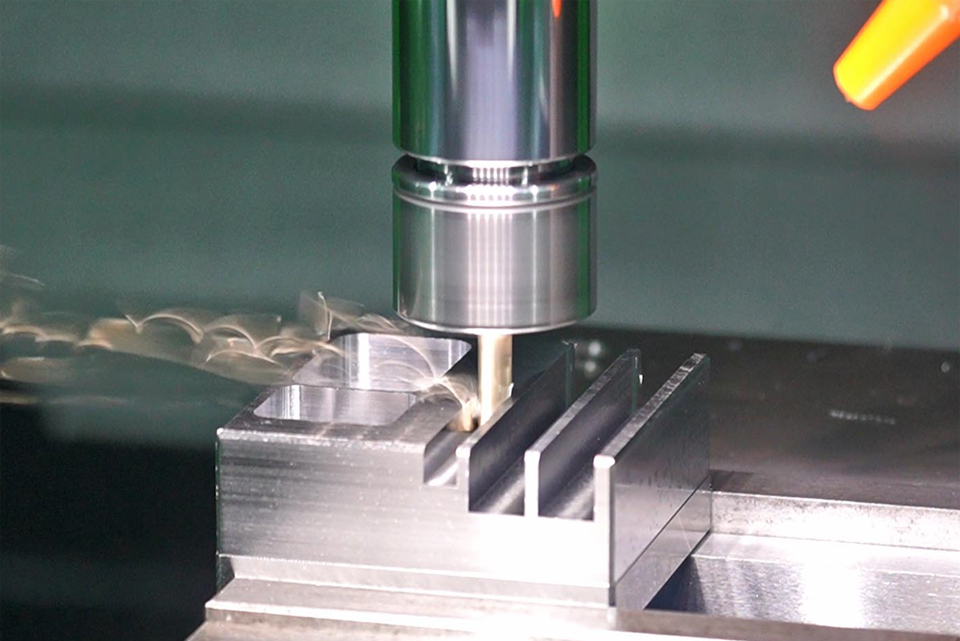

A carbide end mill is a high-performance cutting tool used in CNC machining and manual milling operations to remove material efficiently while maintaining high precision. Compared to traditional cutting tools, carbide end mills for aluminum offer superior hardness, heat resistance, and durability, making them ideal for machining lightweight metals like aluminum.

Common Applications of Carbide End Mills

As professional carbide cutter manufacturers, Our design aluminum milling cutters specifically for high-speed machining and smooth finishes in a variety of industries:

- Slotting – Creating precise keyways, grooves, and pockets.

- Profiling – Shaping and contouring aluminum surfaces.

- Drilling & Plunging – Acting as an alternative to standard drill bits.

- Facing – Producing flat, polished surface finishes.

- Engraving & Fine Detailing – Perfect for intricate designs in aluminum and soft metals.

Why Choose Carbide End Mills for Aluminum?

- Optimized Flute Design – Improves chip evacuation and prevents aluminum buildup.

- High-Speed Machining – Handles rapid cutting speeds while maintaining precision.

- Non-Sticky Cutting Edge – Polished surface reduces adhesion when machining soft metals.

- Durable & Long-Lasting – Built from premium carbide materials to extend tool life.

Trusted Carbide Cutter Manufacturers for Precision Machining

As a leading carbide cutter manufacturer, we specialize in high-performance aluminum milling cutters engineered for maximum efficiency and durability. Whether you need standard end mills for aluminum or custom carbide end mills for aluminum, our cutting tools are designed to optimize productivity and surface finish.

Looking for the right carbide end mill for aluminum machining? Contact HD. today for expert recommendations!